Uhlmann Completes Major Serialization Project for Salutas

Uhlmann Completes Major Serialization Project for Salutas

The project involved the upgrading of 47 packaging production lines within one year to Uhlmann Serialization Platform USP

Uhlmann executed a major serialization project for Novartis' Salutas Pharma to implement the EU's Falsified Medicines Directive

The task involved the upgrade of 47 production lines within one year. Prescription medicines in the EU must be marked with a unique identification number as of February 2019. A tamper-evident form of closure is also required to prevent manipulation. The implementation of these serialization and tamper-evidence specifications entails much effort on the part of the pharmaceutical manufacturers, and means intervention in sensitive processes. Salutas Pharma and LEK, both subsidiaries of Sandoz companies belonging to the Novartis Group, addressed these challenges together with Uhlmann.

The Salutas sites in Barleben and Osterweddingen are among the most modern and efficient pharmaceutical production facilities in Europe. “Around eight billion tablets and capsules leave our Barleben plant alone in a year”, reports Kay Reinhardt, team leader engineering Projects at Salutas Pharma. “Altogether, it was 26 packaging lines in Barleben and Osterweddingen that we had to modify appropriately.”

In addition, the Polish affiliate LEK was planning a project of similar scale. This increased the number of lines to almost 50. The upgrading of so many practically identical lines poses a major mechanical engineering challenge. Added to this, the generics manufacturer had stipulated an extremely tight time schedule in order to keep costly downtimes short and avoid supply shortages. W

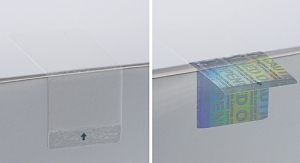

The project partners defined the machine and project details in mid-2016 and drew up an ambitious implementation plan. Salutas opted for the compact Uhlmann Serialization Platform USP. The module-based platform incorporates components for weighing, printing, inspection, and tamper-evident labeling. The serialization process involves the marking of the cartons with a 2D data matrix code, which is read by a camera and transmitted in real time to a site server. “We worked with Uhlmann to adapt the machine and the software so everything optimally meets our requirements”, adds Kay Reinhardt.

Having finalized a pilot machine in May 2017, the actual roll-out – dealing with six lines at a time in one block – began in October 2017.

The last machine was released for production at the end of September 2018 and the technical installation completed. The teams will concentrate on correcting the usual teething problems in the coming weeks so that production complies with all the EU specifications at the beginning of February 2019.